Abstract

In this paper we present a wireless sensor for the monitoring of food quality. We integrate sensing capability into ultrahigh frequency (UHF) radio-frequency identification (RFID) tags through the relationship between the physical read-range and permittivity of the object we label with the RFID tags. Using the known variations of food permittivity as a function of time, we can detect the contamination time at which a food product becomes unacceptable for consumption based on the measurement of read-range with the as-designed sensing tags. This low-cost UHF RFID passive sensor was designed and experimentally tested on beef, pork, and cheese with the same storage conditions as in supermarkets. The agreement between the experimental and simulation results show the potential of this technique for practical application in food-quality tracking.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

Today radio-frequency identification (RFID) technology is growing rapidly and has many applications in various areas of daily life. This technology offers many advantages such as automatic capture and contactless data via a smart label (commonly called a tag) [1], and can also save time and reduce labor costs. Moreover, ultrahigh frequency (UHF) RFID can store large amounts of data and have a potentially unlimited lifespan [2]. The combination of RFID tags with sensing capability is a recent development in the field of RFID [3].

The automatic control of quality in agriculture, pharmacy, and food industries has attracted the interest of researchers in both education and industry. The fast and accurate identification of contaminated or disqualified products is a worthwhile research problem to ensure food safety. However, the cost of current systems integrated with specific sensors (based on biochemical, infrared spectroscopy, and temperature spectrum methods) is still prohibitive and time-consuming and therefore impractical for most applications. As discussed in [4], some applications of electromagnetic techniques to monitor the freshness of food products have been reported.

One such application is the use of RFID active tags combined with specific sensors that are mounted directly on RFID tags such as with a wireless identification sensing platform (WISP) [5], in which the signals from the RFID chip as well as from environmental factors can be collected and transferred to an RFID reader through radio channels. According to this work, the power transmitted from the RFID reader can be used not only to activate the chip on the sensing tags, but also for the operation of the integrated sensor on this module. This leads to an internal battery to increase the operation distance between the tag reader for this kind of sensing device [2], which limits the operational lifetime and increases the cost of the sensing modules.

Ong et al [6] proposed an analytical formula to calculate the permittivity of food products during the increase of bacteria concentration through the impedance of embedded structure in food products. In this work an analytical equation of the permittivity and modification in impedance of an RF structure embedded inside food products (meat and beer) in order to estimate the threshold bacteria concentration of contaminated food products was determined. Ghatass et al [7] estimated the freshness of beef by calculating the permittivity and conductivity measured from both capacitance and inductance. These approaches still remain difficult in practical applications because of their complex set-up and need for a new standard of signal processing for data acquisition from embedded devices inside food products.

Another study proposed an integrated gas-sensing function into UHF RFID passive tags by coating sensitive material (single-wall carbon nanotube) on the antenna surface of UHF RFID passive tags [8]. In ambient atmosphere, the fabricated prototype of the antenna structure (without coating sensitive material) was impedance matched at the desired resonant frequency (868 MHz for UHF RFID band). When the ambient environment changed from air to ammonia (NH3), the reflection coefficient decreased significantly at the same resonant frequency, which lead to a decrease in the signal to the RFID reader. This work demonstrates the application of a passive UHF RFID system for detecting and warning of toxic gases in the case of leaking emissions. However, this approach is based on the modification of the reflection coefficient (without the RFID chip on the tag) and requires a specific RFID reader for both extracting the impedance of the coated tag's antenna and detecting the modification in the structure's impedance function to different gas concentrations.

In a related work [9], Marrocco et al proposed a different approach to profit from the electromagnetic effects of the object (labeled by the UHF RFID tags) on the read-range of UHF RFID tags. In this work, the authors showed that more information about the identified object by the UHF RFID tags can be obtained and it is unnecessary to integrate specific sensors. Indeed, we know that UHF RFID tags are sensitive to the object or product on which it is labeled. When the identified objects change, a modification in physical characteristics that can change the electromagnetic interaction between the UHF RFID tag and the transmitted electromagnetic field from the RFID reader occurs. Using this approach, we can use currently available hardware platforms and the communication protocol of UHF RFID systems but the permittivity of the identified objects must be different enough so the RFID reader can detect the modification in physical read-range between the tags and reader.

In this work we propose transforming the UHF RFID passive tags into real-time wireless sensors for food-quality detection. We use conventional UHF RFID passive tags and exploit the sensitivity of tag antenna to its environment through the permittivity of food products. For this purpose, we measure the modification of a food product's permittivity as a function of time to define the physical parameters at the point of contamination. From this database, we then consider different antenna structures to choose the most sensitive design to detect a food product's permittivity as a function to time by using a simulation model with the commercial simulator, CST Microwave Studio®. Then, we continue to integrate the sensing capability into UHF RFID passive tags and improve the reliability of the system by multi-chip/multi-antenna configuration. The theoretical background of the operational mode of detection for passive UHF RFID tags is presented in section 2, the method of design is presented in section 3, the experimental results are presented in section 4, and the conclusions are presented in section 5.

2. Theoretical background

From the theory of antennas and propagation we know there are mathematical equations for the electromagnetic parameters of a radio frequency structure (i.e., impedance, gain, polarization) and the permittivity of substrate on which the structure is fabricated [10]. Thus, the change in an identified object's permittivity, which is labeled by the UHF RFID tag, leads to the variation of the RFID tag's parameters such as gain and impedance of the antenna structure as well as the read-range of the RFID tag according to the Friis formula [2]:

where r is the read-range of the tag, λ is the wavelength, PtGt is the maximum transmission power depending on the UHF RFID regulation, Gr is the gain of RFID tag's antenna, τ is the power transmission coefficient between the chip and antenna, and Pth is the activation power of the chip.

According to the Friis formula we can conclude that the read-range of the UHF RFID tags can be influenced by the transmission coefficient and gain of the tag's antenna. Furthermore, the transmission coefficient from antenna to chip and the gain of the antenna depend on the permittivity of the substrate on which the antenna is fabricated according to the theory of antenna design [10]. As a result of the above analysis, a physical relation between the permittivity of object and the read-range of the UHF RFID tag is found, which is mounted on the identified object.

Thus, UHF RFID tags are typically designed to work properly (i.e., to ensure the stability of the read-range between the readers and designed tags) at some certain value of permittivity. As stated above, if the UHF RFID tag is labeled on an object with different permittivity than the original design, both the antenna's impedance and the gain of the antenna will change and modify the read-range of the RFID tag. This phenomenon usually reduces the performance of UHF RFID tags due to loss of impedance matching as well as the electromagnetic radiation. However, some proposed methods have improved the robustness of UHF RFID tags. In fact, the proposed design methodology can maintain the effective bandwidth of the read-range and ensure the impedance matching between the chip and antenna for UHF RFID tags with different permittivity [11].

In this work we will use the nature of mismatching of different values of permittivity to integrate the sensing capability of the passive UHF RFID tags without specific sensors on it. When an UHF RFID tag is placed on different objects, the modification of physical parameters (permittivity of material) will change the corresponding performance of the RFID tags by shifting the physical read-range between the tag and reader. The change in read-range can be explained by the fluctuation in impedance matching between the antenna and chip as well as the radiation parameters such as gain, polarization of tag's antenna, etc, which means there is some mathematical expression between the read-the range of the RFID tag and the permittivity of the object on the RFID tag labeled to retrieve information from the identified object. This approach does not need specific sensors to take advantage of the available hardware and protocols of current UHF RFID systems. As a result, it reduces the cost of the system compared to other approaches and provides better feasibility for practical applications.

In [12, 13] it was shown that both dielectric constant and loss factor of food might be influenced by environmental factors such as temperature, humidity, frequency, structure of muscle, internal ingredients, and preservation time. Therefore, considering the environmental impact on storage conditions is important for controlling measured permittivity. As found in [13], storage temperature and humidity are the most significant factors affecting the measured results of dielectric constant and loss. Thus, it is important to keep the temperature and humidity of experimented samples as close as possible to practical conditions to optimize the accuracy of the simulation model of the designed RFID sensing tags.

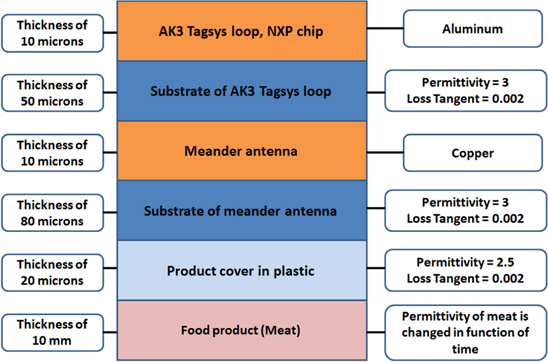

Figure 1 shows the geometry of a typical RFID tag designed to be sensitive to its environment, represented by direct contact with food to be monitored and assumed to be 1 cm thick. Based on data from [12, 13], the permittivity of a certain food product will change as a function of time due to degradation by bacteria. We consider a product whose permittivity is between 40 and 80, based on data from [12, 13], which leads to a change of the antenna's impedance and modifies the matching between the antenna and the RFID chip and therefore the power activation of the tag [2].

Figure 1. Proposed geometry of antenna for the demonstration of the food permittivity effect on RFID tag.

Download figure:

Standard image High-resolution imageFigure 2 presents the change of impedance of the antenna for this range of permittivity, which shows a significant change in both the real and imaginary parts of the impedance of the tag antenna. As discussed above, this change also modifies the power transmission coefficient τ and read-range of the RFID tag. Thus, if we can determine the modification of the food's permittivity as a function of time, we can detect the quality change through the physical read-range in practical applications.

Figure 2. Impedance (a) and read-range (b) of the proposed design as a function of permittivity modification.

Download figure:

Standard image High-resolution imageIn this work we base the design of the sensor tag on the variation of the read-range distance. For this purpose, two tags were designed for different values of permittivity of a food sample (beef), which loses its freshness to reach a state of contamination beyond what is safe for consumption. The sensor tag was designed to meet the minimum read-range at the stage of food contamination with only one tag. However, it is possible to increase system reliability by adding another tag at the distance d from the first one. The second tag is also designed to have the minimum read-range at the contamination time but with its radiation pattern now orthogonal to the maximum direction of gain of the first tag. All the simulations use data from the European Telecommunications Standards Institute (ETSI) regulation of UHF RFID (resonant frequency at 868 MHz).

3. Simulation and design

The design flowchart is shown in figure 3. We start with the study of food permittivity (meat and cheese) as a function of time with the same storage conditions as in a supermarket. From the database of food permittivity, we define the contamination time and corresponding permittivity as a physical factor of the simulation model. Next, we use antenna structures sensitive enough for the design of RFID sensing tags for food-quality detection inspired from related works [14–20]. The integration of sensing capability of the proposed antenna structures was executed on a 3D EM simulator (CST Microwave Studio®) to get the desired read-range and radiation pattern. Finally, we evaluated the fabricated prototype RFID sensing tags for practical applications as will be described as follows.

Figure 3. Design methodology of sensor RFID tag.

Download figure:

Standard image High-resolution imageThe simulation parameters were imported into CST Microwave Studio® as detailed in figure 4. From the related literature and our executed works [14–20], some proposed structures of transformed dipole antenna were applied for the design of the sensing tags. As is known, the classical dipole is always sensitive to the environment it is embedded in, but the structure of the classic dipole with the dimensions of around half a wavelength (around 16.7 cm at UHF band) is not feasible for practical applications. Therefore, we used miniaturization Tip-loading, T-load, folded dipole, and meandered dipole techniques to both reduce the size and keep the impedance matching between the chip and antenna of the RFID tag. From the above analysis, we chose typical structures and modified the electromagnetic parameters (e.g., impedance, gain, read-range) by changing the permittivity of the identified objects with the RFID tags.

Figure 4. Simulation model of sensing tag design.

Download figure:

Standard image High-resolution imageIn the first step we consider three structures based on meandered dipole antennae, labeled A-1, A-2, and A-3 (figure 5). In this work we focus on the frequency 868 MHz (corresponding to the center frequency of the UHF RFID regulations in Vietnam and from ETSI) to consider the effect of object permittivity on the tag's parameters such as antenna impedance and read-range. However, all the parameters (permittivity and thickness of substrate and antenna dimensions) were imported into the simulation model as shown in figure 4. The unique parameter, which is varied in this step, is object permittivity where the RFID tags are labeled on (corresponding to the bottom layer in the model). The value of the object permittivity was changed from 40 to 80 according to the literature [12, 13]. As discussed, we consider the fluctuation of physical parameters due to the variation of food permittivity at a determined frequency (868 MHz) for three proposed antenna structures.

Figure 5. Proposed antenna geometries for design of RFID sensing tag.

Download figure:

Standard image High-resolution imageAs figure 6 shows A-2 has the largest modification in the resistance of antenna impedance, while structure A-1 has the biggest change in reactance of antenna impedance. The antenna impedance of structure A-3 has smaller variation compared to A-1 and A-2 (figures 6(a) and (b)). However, the fluctuation in gain of A-3 (around 7 dBi) leads to a remarkable change in read-range (figures 6(c) and (d)). As discussed above, the changes in antenna impedance and gain lead to variation in both power transmission coefficient and read-range of the RFID tags by the Friis formula.

Figure 6. Effect of permittivity modification on the performance of the proposed design (impedance, gain, and read-range).

Download figure:

Standard image High-resolution imageAs the simulation results in figures 6(c) and (d) show, we can conclude that structure A-2 is more sensitive to gain fluctuation than the other antenna structures (around 8 dBi). However, the structures A-1 and A-3 still have significant change with values larger than 7 dBi. Thus, we can conclude that the antenna gain and the tags' read-range are greatly reduced when the dielectric constant of the food product increases for all three proposed structures. Furthermore, the shapes of the gain and read-range curves are similar, which means the antenna gain has more effect on the final design's read-range. This was expected since the antenna gain is related directly to the dielectric constant of the dielectric substrate layer underneath the RFID sensing tag.

The proposed structures are also sensitive to variation in food permittivity with significant change in read-range (from 65 cm to 110 cm). In particular, the proposed structures can sense food-quality variation by significant read-range variation in the contamination range (the permittivity varies from 55 to 65). We define the most sensitive structures for the design of RFID sensor tags in the following steps.

To design the sensor tag, we use a variation in read-range distance. We also use the multi-tag concept as given in [9]. The sensor tag was designed to meet the minimum read-range at the state of contamination and the system can detect the contamination of food with only one tag. However, we add another tag with the distance d from the first tag to increase system reliability as shown in figure 7. The second tag is also designed to have the minimum read-range at the contamination time but the radiation pattern will be in the perpendicular direction compared to the maximum gain direction of the first tag. All the simulations focus on the ETSI regulation of UHF RFID with the resonant frequency 868 MHz.

Figure 7. Model of simulation for sensor tag design.

Download figure:

Standard image High-resolution imageBoth tags are designed to have the worst read-range corresponding to the permittivity of the contaminated state of the food product. We chose the values of the contaminated meat and cheese that correspond to the permittivity of meat and cheese at contamination (at 120 h and 600 h as found in the above experiments, respectively). The results from the 3D EM simulator CST Microwave Studio® show that the most sensitive structure for meat-quality detection is A-2. Next, the distance d between the two RFID tags is optimized from 1 cm to 8 cm, and the two tags are mounted on the meat with the imported permittivity from the experimental results above. The results show that the optimized distance d should be 3 cm to maintain the desired radiation patterns.

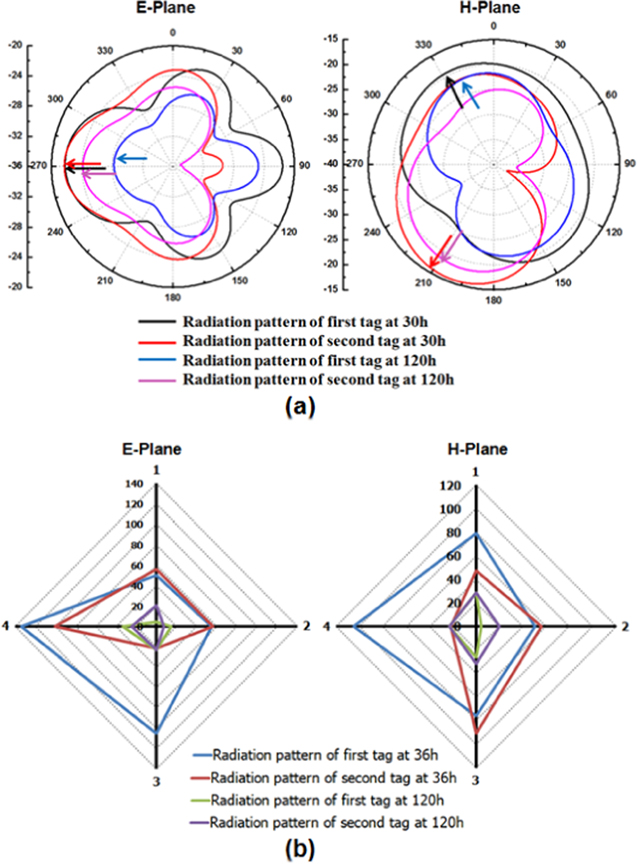

According to figure 8(a) the read-range of each tag reaches the minimum value at 120 h and the radiation pattern of each tag keeps the same shape over time. In figure 8(b) we can see that the radiation pattern of each tag is almost unchanged, which leads to the maximum radiation being scalar as a function of time. Moreover, the direction of the maximum radiation is almost perpendicular for each antenna, although the gain of each antenna is changed as function of time. Additionally, the difference between the maximum and minimum read-range of each tag is acceptable (37 cm and 26 cm) and for the detection of two states of food (fresh and contaminated). In the maximum direction of radiation, the maximum read-range and minimum of each tag are obtained after 30 and 120 h, respectively, and are also perpendicular to each other. Thus, we can increase the reliability of the system by using two readers installed perpendicularly.

Figure 8. (a) Read-range at maximum direction and (b) 3D radiation pattern of design RFID sensor in function to time of design A-2.

Download figure:

Standard image High-resolution imageAs shown in figure 8 the read-range of each tag reaches a minimum value at 120 h, and the radiation pattern of each tag maintains the same shape over time. Figure 8(b) shows that the radiation pattern of each tag changes little, which means the direction of maximum radiation for each tag is also the same as a function of time. While the gain of the antenna is changed the directions of maximum radiation are almost perpendicular to each other. In addition, the difference between the maximum and minimum read-range of each tag is acceptable and feasible in practice (0.31 m and 0.2 m). For application, because the maximum read-range is obtained after 30 h and the minimum is obtained after 120 h perpendicularly, we can use two UHF RFID readers to detect the state of contamination as function of time as shown in figure 9.

Figure 9. Potential application of proposed designs.

Download figure:

Standard image High-resolution imageUsing a similar design method, we chose A-1 as the most sensitive structure for cheese-quality detection (figure 10). The aim of the sensing tag design is to have the worst read-range of both tags at a permittivity of 600 h as in the above experiments. Then, the distance d between the two tags will be optimized from 1 cm to 8 cm to define the desired radiation patterns. In these simulations, the sensing RFID tag (with both chip/antenna pairs) is mounted on the cheese with the imported permittivity from the experimental results above. The optimized results show that the optimized distance between the two tags is 1 cm as shown in figure 10. With d = 1 cm, the maximum communication direction of the two tags is the same. With the distance d between the two tags, we can adjust both the gap in read-range (the difference between the maximum and minimum values) and the maximum direction between the two tags according to the application. In fact, we have both the perpendicular configuration (design A-2) and parallel configuration (design A-1).

Figure 10. Simulated results of sensing tag A-1 for cheese-quality detection. (a) Read-range at maximum direction and (b) radiation patterns of each pair antenna/chip as a function of time.

Download figure:

Standard image High-resolution image4. Experimental results and discussion

We use the Speedway Revolution R420 of Impinj®. The sensor tag prototypes (figure 11) are mounted on the food sample to define the 3D read-range of the fresh state to the contamination state (7 consecutive days for meat and 30 consecutive days for cheese). The measurement sessions are executed every 12 h as in the permittivity experiments.

Figure 11. Prototypes of sensor tag design (A-1 and A-2).

Download figure:

Standard image High-resolution imageFrom the measured read-range of the A-2 design described in figure 12, the difference between simulated and measured read-range can be explained by the accuracy between the permittivity's database (caused by the difference in temperature and thickness of the beef sample). Furthermore, the contamination time of sensor tag A-2 is still between 96 and 120 h as in the simulation. From the results in figure 13 we can see that the directions of maximum read-range corresponding to each tag are quasi-perpendicular each to other, which proves the feasibility of this system for food-quality detection in a real application. The mismatch between the simulation and the measurement can be explained from theories in literature. We know that the permittivity at contamination can be changed if environmental storage conditions such as temperature and moisture content are changed [13]. Thus, we consider the read-range and permittivity as a function of environmental factors such as temperature and moisture content to define the sensitivity and the performance error of the RFID sensor tag.

Figure 12. Simulated and measured read-range of sensor tag A-2.

Download figure:

Standard image High-resolution imageFigure 13. 3D radiation pattern of design A-2 in E-Plan and H-Plan. (a) Simulation of 3D radiation pattern with optimized distance d = 3 cm. (b) Measurement 3D red-range of fabricated prototype.

Download figure:

Standard image High-resolution imageAs shown in figure 14 for the design of cheese-quality detection A-1 the curves of the read-range show a similar trend and the simulation and contamination time of both tags is around 600 h, since the contamination of cheese is longer compared than meat (around after 600 h). For this reason, the measurement step (every 12 h) is stable enough for the cheese characterization, especially between 560 h and 640 h. In contrast, the 12 h step could be reduced (e.g., 6 h step at the contamination) to detect the fluctuations in the read-range for meat contamination. Furthermore, the mismatch between simulation and measurement can be similarly explained by the environmental effects (e.g., temperature and moisture content) on food permittivity at the contamination time. However, the good agreement between simulation and measurement validates the feasibility of the proposed designs for real-world applications.

Figure 14. Measured results for A-1 design at maximum direction of read-range.

Download figure:

Standard image High-resolution image5. Conclusion

In this paper we proposed an approach for using passive UHF RFID tags to detect the contamination of food products. The experimental and simulation results showed the potential of this technique for practical application of food-quality tracking. In addition, the results of this work allow considering the use of this approach for medical applications, in the form of biomedical applications such as wearable antenna to detect the cancer tumor. A sensitivity study should be conducted to better optimize the sensor and predict its performance. As is known, the permittivity of human muscle and tissue is close to the permittivity of meat such as pork or beef.

Furthermore, an in-depth study should be executed to improve the performance of the proposed designs. In particular, we need to reduce the effect of ambient temperature on measured permittivity. Next, the sensitivity of the proposed designs on the function of food permittivity should be considered to test the performance of the sensor tags. It's also necessary to consider the effect of environmental conditions on the performance of the proposed designs (i.e., antenna impedance or tag read-range). Finally, we think the improvement of this technique by a three-tag configuration design (as in a three-sector cell-phone base station) could enhance the operational angular in practical applications.

Acknowledgments

This research is funded by Laboratory for Nanotechnology LNT, Vietnam National University in Ho Chi Minh City under grant LNT-2013-01. This work was developed in collaboration with a research project on RFID between the LNT in Vietnam and the LCIS in France with AK3 Tagsys loops kindly provided by Mr Christophe Loussert. The authors would like to thank Keysight® Vietnam for the use of measuring equipment during research.